Acrylic Glove Boxes See Surge in Demand Across Medical and Research Sectors

Published:

2025-05-23

As global industries place greater emphasis on safety, cleanliness, and controlled environments, acrylic glove boxes are emerging as a critical tool across multiple sectors — particularly in healthcare, biotechnology, pharmaceuticals, and semiconductor manufacturing.

As global industries place greater emphasis on safety, cleanliness, and controlled environments, acrylic glove boxes are emerging as a critical tool across multiple sectors — particularly in healthcare, biotechnology, pharmaceuticals, and semiconductor manufacturing.

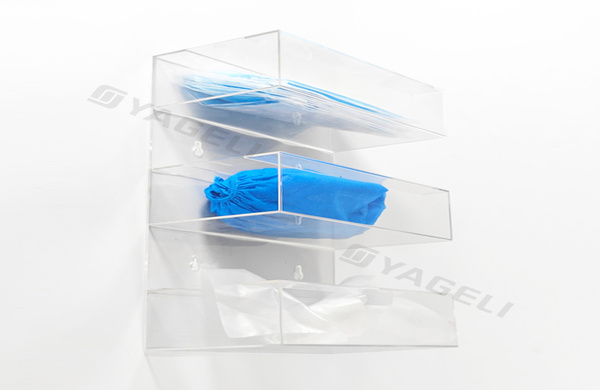

Acrylic glove boxes, made from clear, durable polymethyl methacrylate (PMMA), offer a transparent, sealed chamber allowing users to manipulate materials in a contaminant-free space. Unlike their stainless-steel counterparts, acrylic units are lighter, more cost-effective, and offer excellent visibility — essential for delicate procedures.

"In medical laboratories and cleanroom applications, visibility is just as important as isolation. Acrylic glove boxes provide both," says Dr. Karen Liu, a biomedical researcher at a private lab in Singapore. "Their chemical resistance and customizable design make them ideal for a wide range of scientific processes."

The surge in demand has been fueled in part by the post-pandemic focus on biosafety and infection control. Hospitals, testing centers, and pharmaceutical firms have ramped up investments in sealed containment systems to ensure sterile handling of samples and materials.

According to a recent market analysis by TechNav Insights, the global glove box market surpassed $500 million in 2024, with acrylic models accounting for over 40% of total units sold. The report forecasts a compound annual growth rate (CAGR) of 6.8% through 2028.

Beyond healthcare, acrylic glove boxes are also making inroads in electronics manufacturing, where dust-sensitive components require meticulous handling. Their modular structure and ergonomic design features are enabling smoother integration into specialized workflows.

However, as demand grows, so do expectations. Users are seeking glove boxes with enhanced airtight seals, anti-static properties, and integrated monitoring systems. In response, manufacturers are investing in R&D to develop smart glove boxes with automated controls, filtration units, and even real-time environmental sensors.

Experts predict that with continued innovations in acrylic materials and growing demand for customized lab infrastructure, acrylic glove boxes will play a pivotal role in next-generation research and production environments.

Latest news